Suzhou days Lai He Automation Technology Co., Ltd.

Contact: Manager Song

Mobile: 13382502797

Tel: 0512-65820216

Fax: 0512-65893517

E-mail: Talach @ tianlaihe. Com

Website: www.tianlaihe.com

Address: North Road, Suzhou High-tech Zone 505

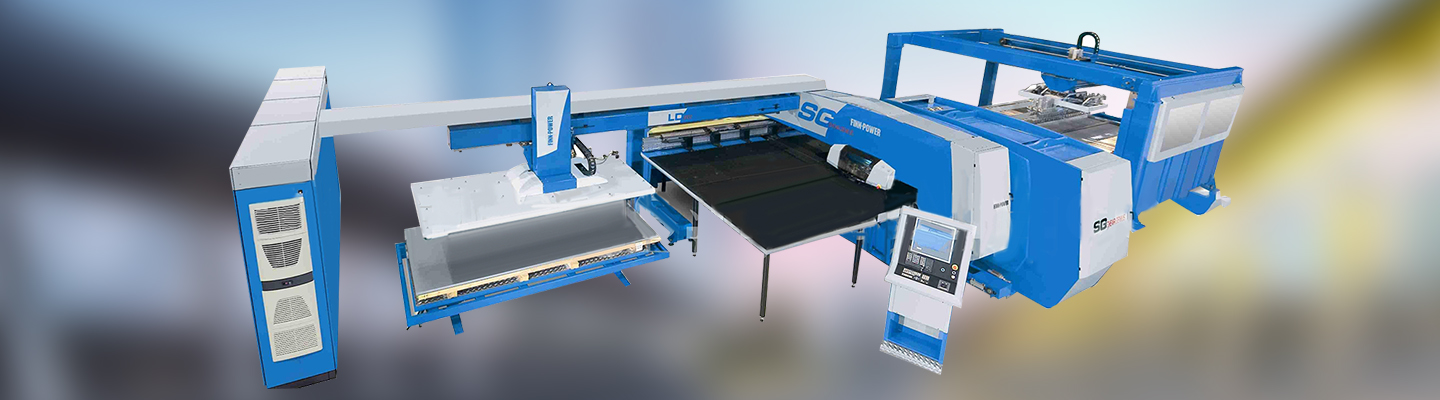

The CNC Vertical Machining Center is an automated machine tool with a programmed control system. The control system can logically process and encode the program with the control coding or other symbolic instructions to operate the machine and machine the part.

CNC machine tools by: mechanical, electrical, hydraulic, lubrication, chip evacuation, and other components.

Machinery includes the turret, screw, spindle, the tailstock, the center frame, bed, shield, knife, turret.

Electrical include: control system control cabinet, control cabinet with servo drives, transformers, relays, contactors, input and output, etc., display screen, motor, travel switch.

Hydraulic include: hydraulic stations, hydraulic pumps, hydraulic valves of various valves, lubrication, lubrication pumps, lubrication lines.

CNC machining features are: precise, fast, suitable for mass production, has nothing to do with the operator experience, high production efficiency, you can process complex shapes, high precision parts, there are some common machine can not or inconvenient to process the parts, Set to after processing multiple processes, processing quality and reduce the labor intensity of those who operate. Chondai Machinery's "full range of manufacturing system integration," including machine maintenance, CNC control. High-precision machinery and CAD / CAM technology has long been inseparable, but only through the integration in order to fully play the performance of the two out of the machinery are made in France Toplet SolidWorks Series TopSolid CAD / CAM software in Taiwan's proxy, you can provide relevant Technical services to help enterprises upgrade and transform their technology.

Take a look at the operation of CNC vertical milling machine, vertical CNC milling machine, the main part of the main base from the column, column, saddle, table, spindle and other vertical CNC milling machine TJ-600 components, of which the body of the five pieces are used High-strength high-quality castings and resin sand molding, tissue stability, to ensure that the machine has good rigidity and accuracy of the retention. Three-axis guide rail are made of high-frequency quenching and plastic guide rail combination to ensure the accuracy of machine tools to reduce friction and wear resistance, three-axis drive system consists of precision ball screw and servo motor system, and with automatic lubrication device.

1, When using handwheel or rapid traverse to move the position of each axis, be sure to read the sign of "-" in X, Y and Z directions of the machine tool and then move it. Slowly move the handwheel to observe the moving direction of the machine before moving to speed up;

2, It is forbidden to open the control cabinet of the numerical control system for viewing and touching without permission;

3, no hard beat control panel, touch the display. Do not hit the table, indexing head, fixtures and rails;

4, CNC vertical milling machine in the process of processing, the operator shall not leave the machine, should keep a high degree of thought, observe the running status of the machine. In the event of abnormal phenomena or accidents, the procedures should be immediately terminated, cut off the power and promptly report to the instructor, may not conduct other operations;

5, Machine control computer, in addition to the program operation and transmission and program copy, not allowed to do other operations;

6, Prohibit the process of measuring the workpiece, manual speed, but can not use the cotton wipe the workpiece, it can not clean the machine;

7, CNC vertical milling machine is a large precision equipment, in addition to workstations placed on workmanship and workpieces, the machine is prohibited stacking any workers, folders, blades, measuring tools, work pieces and other debris;

8, the operator is not free to change the internal parameters of the machine. Internship students may not call or modify other programs not compiled by themselves.

9, Prohibition of contact with the tip and the iron scrap, iron must be used iron hooks or brushes to clean up;

10, Prohibition of tentative operations;

11, Do not touch the rotating spindle, work piece or other moving parts by hand or any other means;

12, in the process of running to be suspended to measure the size of the workpiece, to be completely stopped machine, spindle stop before measuring, so as to avoid personal accident;

13, if the machine does not use a few days, then every other day to deal with NC and CRT part of the power 2-3 hours. The company is located in:

14, shutdown, wait until the spindle stop 3 minutes before shutting down.

Industrial system to provide the foundation.

15, CNC vertical milling machine in the processing of parts, we must close the protective door, not allowed to head, hand into the protective door, the process is not allowed to open the protective door

Lastly, I would like to reiterate that I hope you can strictly abide by the operating procedures when operating any machine. The number of work-related injuries caused by ignoring the operating procedures each year is numerous. Not only will it cause personal injury to my family, but I also must be cautious and follow the process.